Modern sensor and electronics development requires the use of innovative manufacturing technologies. This is why the Fraunhofer Center for Sensor Intelligence ZSI relies on novel processes such as 3D printed circuit board printing.

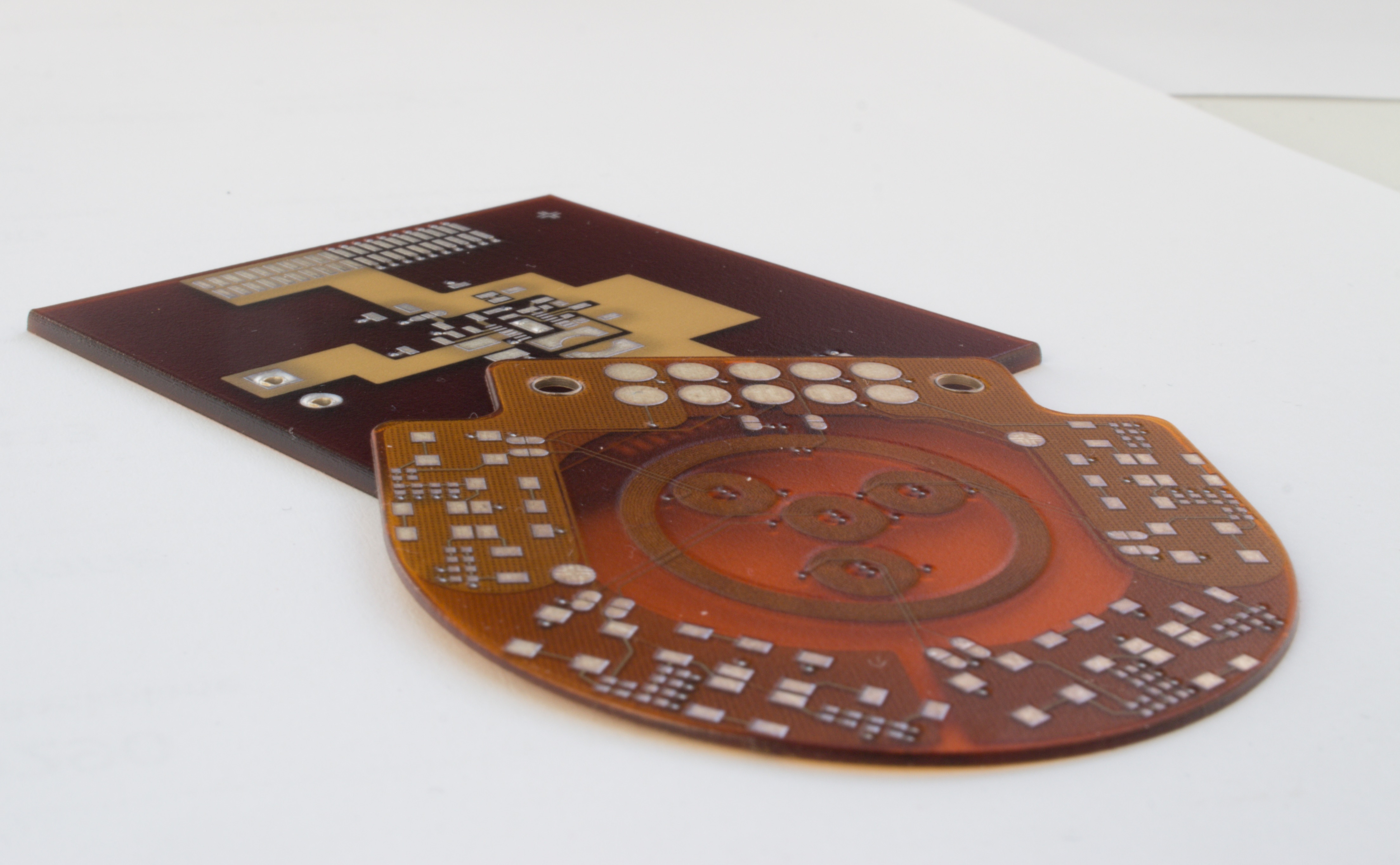

This type of production opens up a multitude of new possibilities for the scientists at the Fraunhofer ZSI, as the classic layer structure familiar from conventionally manufactured printed circuit boards is no longer required.

Instead, the process enables the three-dimensional design of circuit boards, antennas and sensors within the technological and technical limits of the process and the production plant.

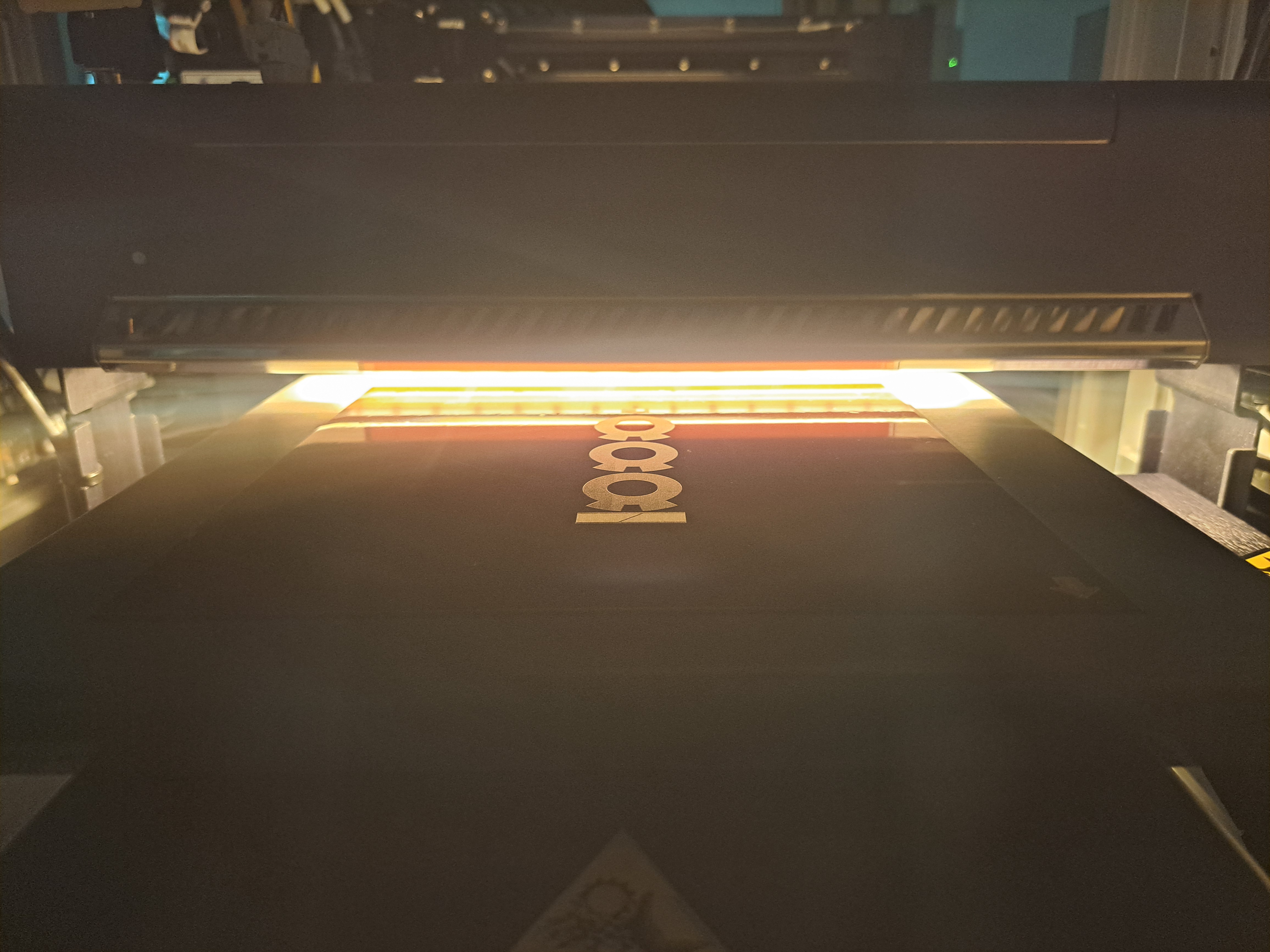

The system used relies on dual inkjet printing. Two different materials, an epoxy resin as a dielectric and an ink mixed with silver nanoparticles, are used as a conductive material for conductor path structures.

Conductor track structures with a minimum width of up to 75 µm and a minimum thickness of 17 µm are technically possible. The installation space of 160 mm x 160 mm x 5 mm can be fully utilized in three dimensions.