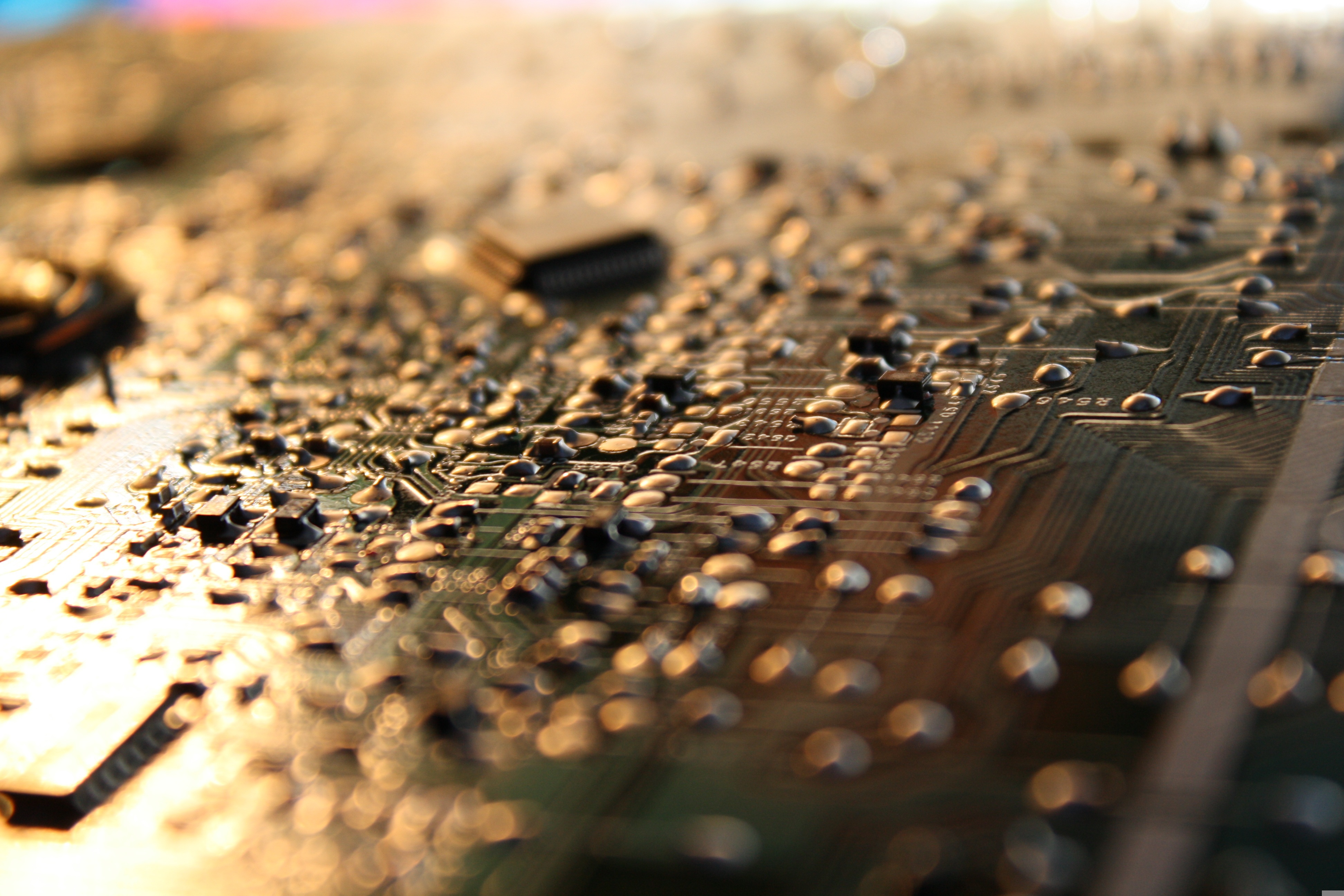

The two vapor phase soldering systems from IBL complete our production line. They can be used to solder both conventional and additively manufactured PCBs quickly, precisely and gently.

Compared to infrared soldering systems, which are often used in small series production and primarily work with top and bottom heat, vapor phase soldering systems are characterized above all by more even heating, more precise temperature control and reduced oxidation in the soldering process.